Pump Spares

Keeping Your Operations Running

at Peak Performance

Our service division specializes in the manufacturing and supply of spare parts for API-standard centrifugal and multistage pumps, providing precision-engineered solutions that ensure reliable performance and extended equipment life. We serve a wide range of industries including oil and gas, chemical, petrochemical, mining, refining, power generation, marine, and pulp and paper. Backed by advanced machining capabilities, experienced technical expertise, and stringent quality control processes, MSG delivers pump spares that meet or exceed OEM specifications, supporting the critical operations of our global clientele.

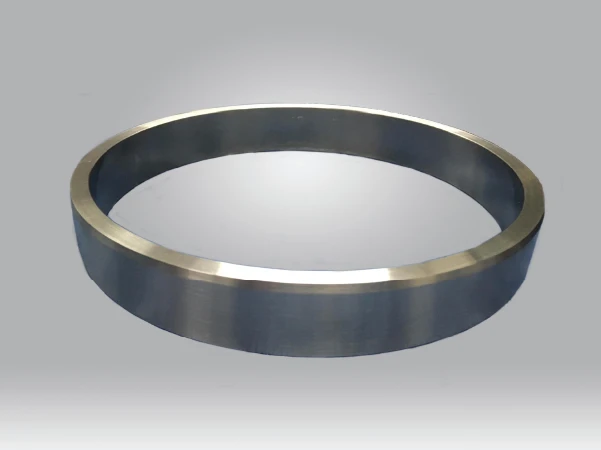

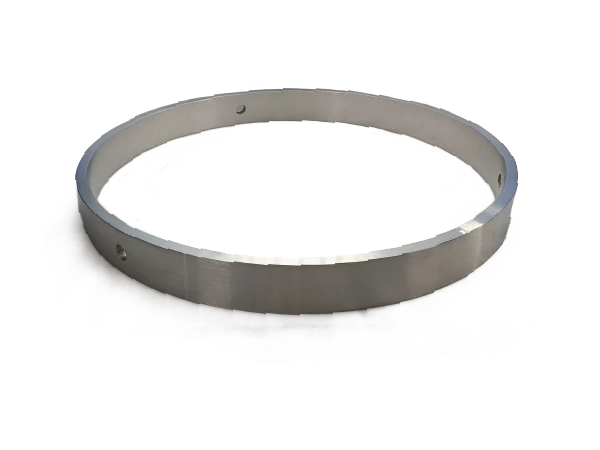

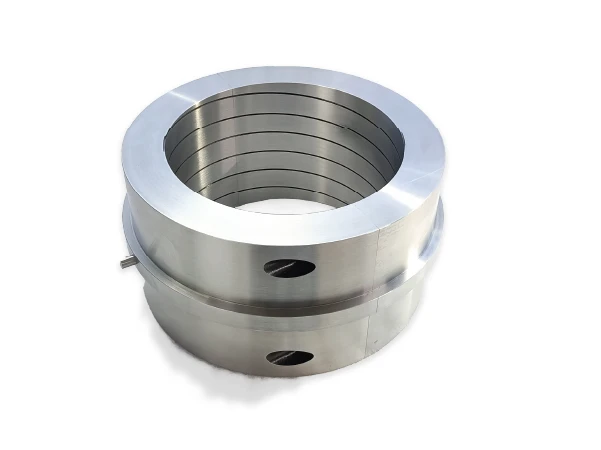

CASING/IMPELLER WEARING RINGS

Wearing rings protect the impeller and casing by maintaining precise clearances in centrifugal pumps. They reduce internal leakage, ensuring high pump efficiency. Over time, wear enlarges the clearance, increasing leakage and requiring maintenance. Replaceable wearing rings allow cost-effective repairs without replacing major components. Regular replacement extends pump life and minimizes downtime.

OPERATING PARAMETERS:

Sizes : 3 inch to 48 inch

STANDARD M.O.C.

• High Nickel Alloy • Stainless Steel (All Grades) • Cast Iron (All Classes) • Bronze (All Grades) • Steel (Low to High Carbon Materials)

Welding & Coatings

• Stellite 1,6 & 12 • Tungstun Carbide • Metco • Colomonoi • Chrome Oxide

Hardning

• Leser Harding

• Heat Treatment

• Hardning & Tempering

FEATURES

• High performance

• Longer working life

• Optimum quality

• Corrosion resistant

PUMP SHAFTS

The pump shaft is the core of the rotor, supporting impellers, sleeves, bearings, balance devices, coupling, and other rotating components. It transmits energy while centering rotating parts to avoid contact with the casing during operation. Proper shaft design controls deflection and ensures smooth performance. Sizing considers torque, deflection, bending, and torsional vibrations. Expertise is required to calculate critical speeds, factoring in damping effects and installation conditions.

OPERATING PARAMETERS:

Diameter : 1 inch to 12 inch

Length : 1 inch to 200 inch

STANDARD M.O.C.

• High Nickel Alloy • Stainless Steel (All Grades) • Cast Iron (All Classes) • Bronze (All Grades) • Steel (Low to High Carbon Materials)

Welding & Coatings

• Stellite 1,6 & 12 • Tungstun Carbide • Metco • Colomonoi • Chrome Oxide

Hardning

• Heat Treatment

• Hardning & Tempering

FEATURES

• High performance

• Longer working life

• Optimum quality

• Corrosion resistant

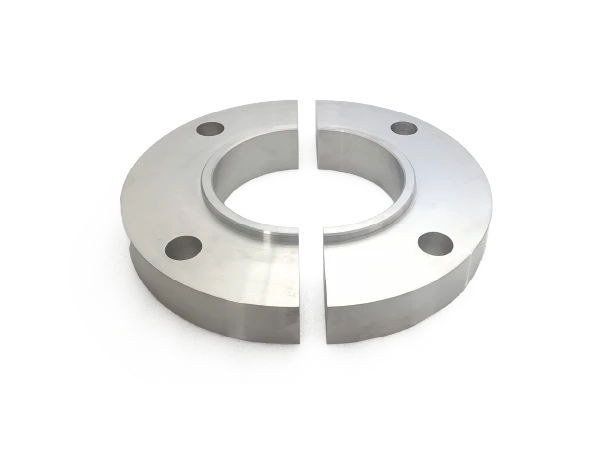

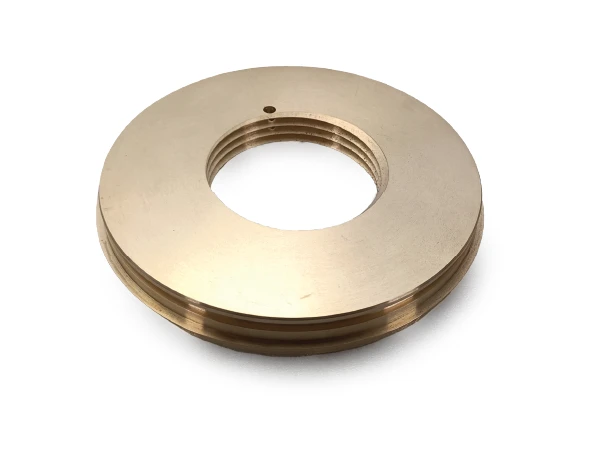

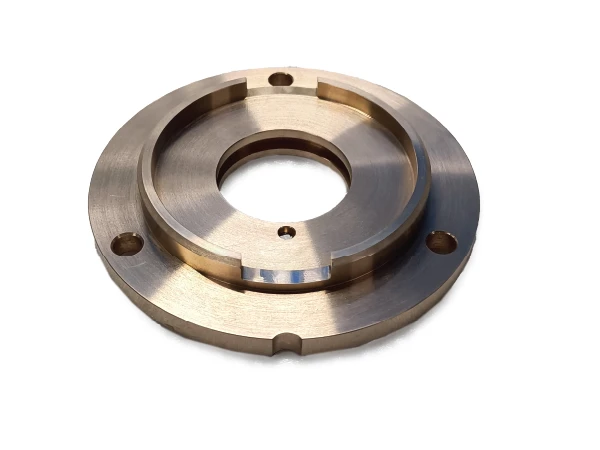

SHAFT SLEEVES

A shaft sleeve is a hollow metal tube that protects the pump shaft from wear, corrosion, and erosion as it passes through packing and seal areas. It safeguards the shaft at critical points like stuffing boxes, bearings, and leakage joints. In multistage pumps, inter-stage sleeves form leakage joints between impellers. Impellers and glands mount on the sleeve, preventing shaft contact with process fluids. Replacing sleeves is cost-effective, preserving shaft integrity and extending pump life.

OPERATING PARAMETERS:

Diameter: 1 inch to 40 inch

Length : 1 inch to 80 inch

STANDARD M.O.C.

• High Nickel Alloy • Stainless Steel (All Grades) • Cast Iron (All Classes) • Bronze (All Grades) • Steel (Low to High Carbon Materials)

Welding & Coatings

• Stellite 1,6 & 12 • Tungstun Carbide • Metco • Colomonoi • Chrome Oxide

Hardning

• Heat Treatment

• Hardning & Tempering

FEATURES

• High performance

• Longer working life

• Optimum quality

• Corrosion resistant

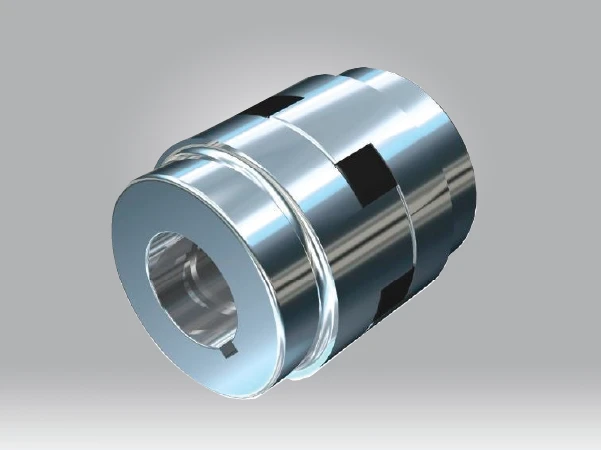

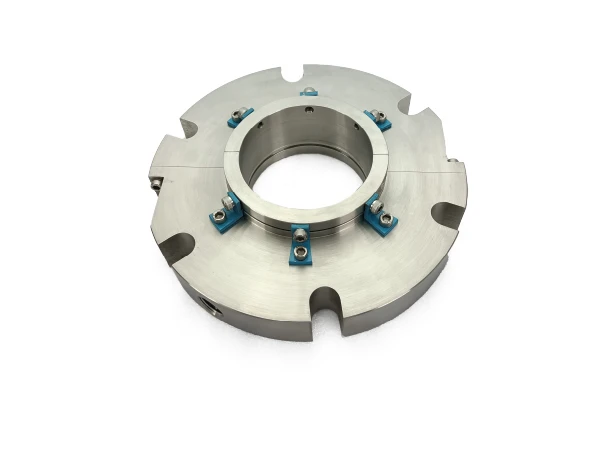

SHAFT COUPLINGS

We manufacture couplings as per customer design and dimensions. All-steel couplings compensate for misalignment, ensuring wear-free, torsionally stiff power transmission. The all-metal design offers high resistance to dirt, temperature, and harsh conditions. Flexible stainless-steel layered rings ensure maintenance-free operation with easy assembly. Custom designs, higher torque capacities, and speeds are available on request.

OPERATING PARAMETERS:

Diameter : 1 inch to 20 inch Length : 1 inch to 50 inch

STANDARD M.O.C.

• Steel (Low to High Carbon Materials) • High Nickel Alloy • Stainless Steel (All Grades) • Cast Iron (All Classes) • Bronze (All Grades)

Hardning

• Heat Treatment

• Hardning & Tempering

FEATURES

• High performance

• Longer working life

• Optimum quality

• Corrosion resistant